Laboratory

AUTOGENOUS SHRINKAGE

PST Method

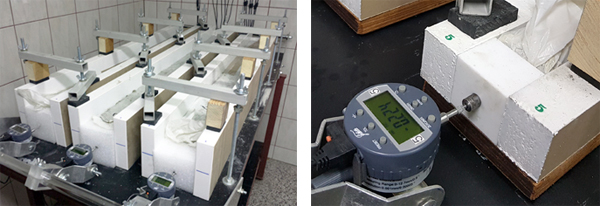

The PST method (Plastic Sleeve Test / Polish Shrinkage Test) is an innovative research solution for measuring autogenous and drying shrinkage of cement composites on a laboratory scale. The cement mixture is molded in plastic sleeves that prevent moisture diffusion from the sample to the environment [1]. The samples are cylindrical, with lengths of 300 mm and diameters of 25 mm (for cement pastes and mortars), 40 mm (for concrete with max dk = 8 mm), and 65 mm (for concrete with max dk = 16 mm). These diameters comply with the EN 12390-1 standard, which requires that the sample's smallest dimension be at least 3.5 times the maximum aggregate diameter. Shrinkage deformations are recorded using digital dial gauges with a resolution of 2 µm or inductive sensors with a resolution of 1 µm, ensuring a measurement accuracy of up to 4 µm/m. The recording of autogenous deformations is done automatically at controlled intervals, starting from the time of sample preparation and continuing for a minimum of 28 days. This method has been successfully validated against other methods for measuring autogenous shrinkage, such as ASTM C1698 and EN 12390-16 [1]. Currently, our laboratory is equipped with 36 digital research stations that, when used simultaneously, allow for advanced studies on the effect of different components and compositions on the kinetics of autogenous shrinkage in reference composites. We also conduct tests under controlled ambient temperatures, with sample temperature monitoring. The PST method is covered by a patent claim [2] and is now standardized under the AASHTO standard in the United States. Below is an example of a measurement:

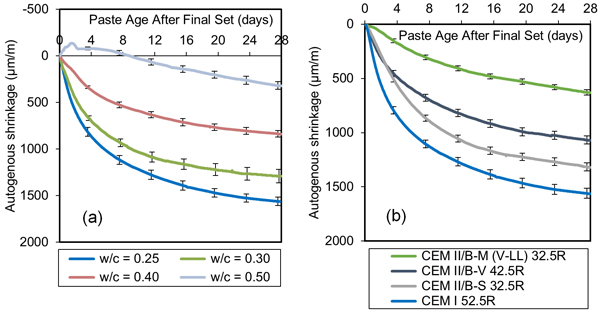

Studies on the autogenous shrinkage of cement pastes:

(a) Effect of water-to-cement ratio (b) Effect of cement type [1].

-------------------------

[1] A. Zieliński, A.K. Schindler, 2024. Plastic-Sleeve Test Method to Measure Autogenous and Drying Shrinkage in Paste, Mortar, and Concrete: Test Results, Measurement 237, 115138. DOI: 10.1016/j.measurement.2024.115138

[2] A. Zieliński. Method of forming a sample for testing the deformation of autogenous materials with a matrix based on a mineral or organic binder in the early and late maturation stage and a stand for this forming. Polish patent PL244502, registered on 11.06.2019 and published 05.02.2024. https://patents.google.com/patent/PL244502B1

Corrugated tube method acc. to ASTM C1698

The Corrugated Tube Method according to the American standard ASTM C1698 allows for the testing of autogenous shrinkage in cement pastes and mortars. The sealing system used has negligible longitudinal stiffness, while the tube diameters (23 and 26 mm) ensure that thermal effects do not interfere with the autogenous shrinkage registration process. Shrinkage deformations are recorded using digital dial gauges with a resolution of 2 µm or inductive sensors with a resolution of 1 µm, with a measurement precision of up to 4 µm/m. Autogenous deformations are automatically recorded at controlled intervals from the moment the sample is prepared, continuing for at least 28 days. Currently, our laboratory is equipped with 3 digital test stations. Additionally, we conduct tests at a controlled ambient temperature with temperature measurements taken from the samples. Below is an example of the results:

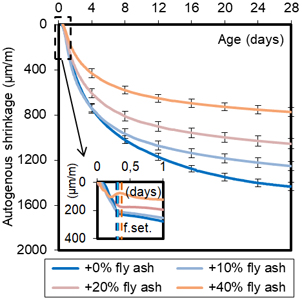

Effect of silica fly ash percentage on the development of autogenous shrinkage in cement pastes. *f.set. - final setting time.

Stand with Adjustable Sample Geometry

This test station features a fixed base with adjustable mounts, allowing for the shaping of forms for 1 to 3 samples with cross-sectional dimensions ranging from 40x40 mm to 150x150 mm and adjustable lengths from 160 mm to 1000 mm. This setup enables the recording of autogenous shrinkage in cement pastes, mortars, and concretes. The cement mixture is placed in a foil at the point of later measurement. The adjustable sample length and shrinkage deformations are measured at two free ends of each sample. When using sensors with a sensitivity of 2 µm, this method achieves deformation accuracies between 2 and 12.5 µm/m. The adjustable sample geometry station is covered by a patent [6]. Below is a sample measurement:

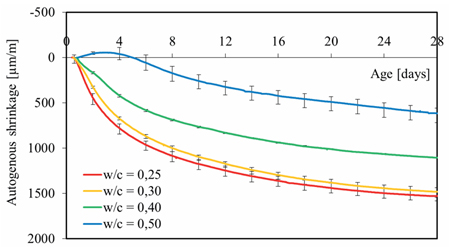

Development of autogenous shrinkage in cement pastes with CEM III/A 42.5N [3].

-------------------------

[3] A. Zieliński, E. Kapeluszna. Analysis of the development of autogenous shrinkage of CEM I 42.5R and CEM III/A 42.5N cement pastes with different water to cement ratios, Cement Wapno Beton, 28(1), 40–55, 2023. DOI: 10.32047/CWB.2023.28.1.4

[4] A. Zieliński, A.K. Schindler, M. Kaszyńska. Cracking risk of high-performance cement composites due to restrained autogenous shrinkage with and without soaked lightweight aggregate, Archives of Civil Engineering 2023;4(4):603-618. DOI: 10.24425/ace.2023.147679

[5] M. Kaszyńska, A. Zieliński. Autogenous Shrinkage in Self-Consolidating Concrete, ACI Special Publication, SP-340, Farmington Hills, MI, 2020, pp. 97-113. (ISBN: 9781641951012)

[6] A. Zieliński. Stand for measuring inherent deformability: swelling and shrinkage of materials with a matrix based on a mineral or organic binder in the early and late maturation stage. Polish patent PL241667, registered on 03.12.2019 and published on 14.11.2022. https://patents.google.com/patent/PL241667B1

Dilatometric Method acc. to EN 12390-16:2020-03

The autogenous shrinkage test method according to European standards was introduced in 2020, included in Annex A of EN 12390-16. Shrinkage deformations are measured on prismatic or cylindrical samples placed in molds. After 1 day, the samples are demolded and sealed with metal or plastic foil or tape. Autogenous deformations are recorded manually or automatically at controlled intervals, from sealing the hardened sample (1 day) to at least 28 days. Our laboratory currently operates 12 digital test stations with the ability to mold prismatic samples with the following dimensions: 40x40x160 mm, 50x50x250 mm (for vertical or horizontal measurement), and 100x100x400 mm (horizontal measurement). Additionally, we conduct tests under controlled ambient temperature conditions.