Laboratory

PLASTIC SHRINKAGE

Linear Shrinkage Drain

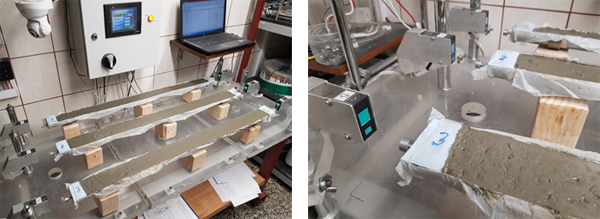

Plastic shrinkage and drying shrinkage tests during the early hardening stage are performed using three individual semicircular linear drains, with diameters of 40 mm for cement grouts and mortars, and 65 mm for concrete mixtures, each 1000 mm in length. Each drain is equipped with two non-contact laser sensors with a resolution of 2 µm, measuring displacement at the two free ends of each sample [1]. The test stand is located in a climate-controlled room with regulated temperature and humidity. Additionally, samples are weighed before and after the tests to analyze water loss and its effect on shrinkage strain values. The system can also record both the material and surface temperatures of the samples. Below is an example of the measurement:

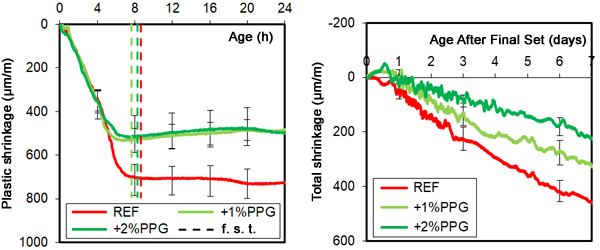

The influence of polypropylene glycol percentage relative to the mass of Portland cement on the development of plastic shrinkage and total shrinkage during early hardening [1].

-------------------------

[1] Zieliński A. Influence of water surface tension-reducing chemical agents on early shrinkage strain in cement composites. Materiały Budowlane. 2024. Volume 624. Issue 8. Pages 5-12. DOI: 10.15199/33.2024.08.02

Linear Layer Method in 3D Printing

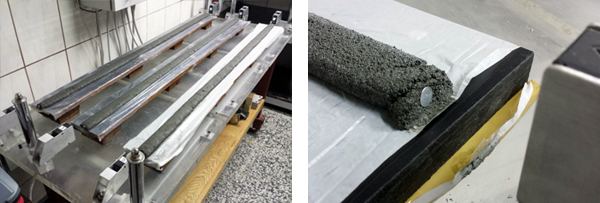

The modernized linear trough system enables measurement of shrinkage deformations in plastic cement mixtures printed as single layers or multilayer structures. This station features an extended measurement space of up to 1350 mm, allowing for more accurate registration of shrinkage deformations with the same high-resolution laser sensors [2,3]. The measurements are automatically archived in the internal memory of the data recording system with a controlled measurement interval. The station can also be equipped with temperature sensors. Below is an example of the measurement:

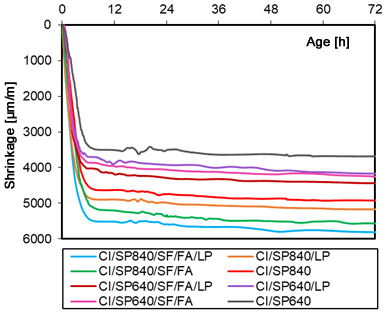

Development of shrinkage deformations in cement mixtures with different binder compositions used in 3D printing [2].

-------------------------

[2] Zieliński A., Skibicki S. Wpływ składu kompozytów cementowych wykonanych w technologii druku 3D na rozwój odkształceń skurczowych, Materiały konferencyjne: Dni Betonu: tradycja i nowoczesność, Wisła, 9-11 października 2023, red. Piotr Kijowski, Jan Deja – Kraków: Stowarzyszanie Producentów Cementu, 2023.

[3] Federowicz K., Kaszyńska M., Zieliński A., Hoffmann M. Effect of Curing Methods on Shrinkage Development in 3D-Printed Concrete, Materials, 13, 2590, s. 1-14, 2020, ISSN 1996-1944, DOI: 10.3390/ma13112590

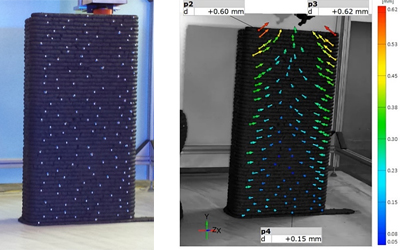

Photogrammetric Method

We perform photogrammetric tests and analyses using the ARAMIS measurement system, which is based on digital image correlation. This non-contact measurement technique operates over an area of 30x30 cm to 500x100 cm, with the ability to analyze data from the entire surface of the material or specific points. The advantage of the ARAMIS system is its ability to perform measurements regardless of the object's geometry or temperature. Additionally, we use full-frame mirrorless cameras with at least 26 MP resolution and fixed focal length lenses. Our software allows us to correlate image scale and analyze deformations with an accuracy of up to 10 µm/m.