Laboratory

SHRINKAGE DEFINITION

Shrinkage in Cement Composites is a natural rheological process, characterized by a reduction in material volume due to water loss or physicochemical reactions. It begins from the moment dry ingredients are mixed with water and continues into the later stages of hardening.Due to the hydration of the binder and the transition from a plastic to a solid state, involving processes such as induction (low binder activity), setting, and hardening, the phenomenon is highly complex. The progression and dynamics of shrinkage deformation depend on several factors, including the proportions and types of components (e.g., fineness of Portland cement and mineral additives, water-to-binder ratio, and the size and type of aggregates) [1,2], the chemical process of cement hydration [1,3-5], pozzolanic reactions from mineral additives (e.g., granulated blast furnace slag, silica fume, fly ash) [2,6-9], moisture exchange between the material and the environment [1,2], and the influence of temperature and carbonation [1,10-12]. Each of these factors uniquely affects both the rate and the ultimate extent of shrinkage deformation.

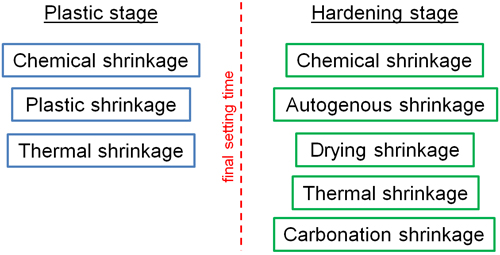

A basic classification of shrinkage deformations due to structural changes from hydration is shown in Fig. 1.

Fig. 1. Types of shrinkage deformations based on the age of the cement composite.

Basic definitions of each type of shrinkage deformation:

- Plastic shrinkage - A reduction in volume in the plastic state due to water loss by evaporation into an environment with lower relative humidity. This process causes capillary menisci to develop, leading to increased capillary pressure, which in turn generates stresses that cause plastic shrinkage deformation [1].

- Chemical shrinkage - A reduction in volume primarily occurring in the early stages of hydration, as hydration products occupy less space than the original reactants (water and cement). This leads to both internal pore formation (reduction in internal volume) and external deformation (autogenous shrinkage) [13].

- Autogenous shrinkage - A reduction in volume caused by the hydration of cement, accompanied by the generation of capillary pressure (self-desiccation), excluding the influence of external loads, temperature changes, or moisture exchange with the environment (i.e., isothermal and sealed conditions) [1,14,15].

- Drying shrinkage - A reduction in volume due to water evaporation from the cement composite into an environment with lower relative humidity. Shrinkage from drying does not occur in proportion to the amount of water lost. While evaporation of free water from capillary pores does not induce shrinkage, the loss of absorbed water during continued drying leads to significant volume reduction [1].

- Thermal shrinkage - A volume change due to temperature fluctuations, either from the exothermic heat generated during binder hydration or from environmental temperature changes. This phenomenon can manifest as expansion (during heating) or contraction (during cooling). The thermal expansion coefficient stabilizes as the composite skeleton forms, typically reaching about 10-13 µε/°C during early hardening [1,11].

- Carbonation shrinkage - A reduction in volume as calcium hydroxide in the cement matrix dissolves and reacts with carbon dioxide to form calcium carbonate. This process, combined with drying shrinkage stresses, increases compressibility in the cement matrix, leading to further volume reduction [1,12].

- Total shrinkage - The overall reduction in volume throughout the life cycle of the cement composite, combining the effects of all shrinkage types. According to the EN 1992-1-1 standard for concrete structure design, total shrinkage is the sum of autogenous and drying shrinkage during the hardening phase of the composite [1].

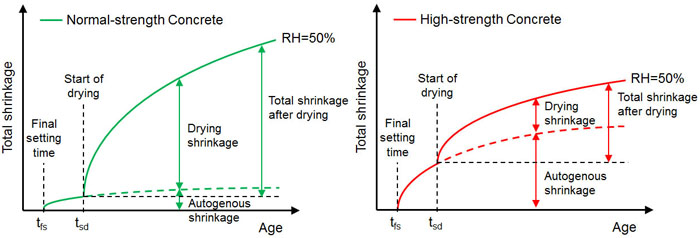

(a) (b)

Fig. 2. Scheme of shrinkage strain development: (a) in ordinary concretes;

(b) in high-performance concretes [16].

Ordinary concretes, typically with compressive strength up to class C50/60 (e.g., 30 MPa after 28 days of curing), are characterized by a high water-to-cement ratio (>0.45), which results in minimal and often negligible autogenous shrinkage but dynamic drying shrinkage that begins once drying starts, such as after demolding. In contrast, high-performance concretes, with compressive strength above class C50/60 (e.g., 100 MPa after 28 days), show a different behavior. Reducing the water-to-cement ratio to the range of 0.20-0.45 and incorporating a high content of reactive binders creates a fine network of capillary pores in the material, leading to reduced drying shrinkage but significantly increased autogenous shrinkage [1,16].

Uncontrolled shrinkage strain development induces tensile stresses in the cement composite structure, which often leads to surface cracking. The larger the surface area exposed to drying (e.g., large bridge decks or industrial floors), the higher the risk of shrinkage cracking. When the tensile stresses caused by total shrinkage exceed the tensile strength of the concrete, cracks may form either at an early stage or even months or years after casting. This results in the penetration of harmful external substances (such as water and salts), leading to reinforcement corrosion and a reduction in the structure's durability, independent of operational load [1,17]. Fig. 3 illustrates examples of shrinkage-related cracks.

(a) (b)

Fig. 3. Examples of concrete structure cracking due to shrinkage: (a) plastic cracks in freshly laid concrete in a floor slab, (b) perpendicular cracks in the concrete cap of a port quay caused by drying shrinkage [17].

To minimize the effects of shrinkage in engineering structures, near-surface reinforcement (in the form of mesh or dispersed steel or polymer fibers) should be applied. Additionally, various treatments to control shrinkage and prevent cracking in cement composites should be considered, including external and internal curing. The most common external curing methods involve protecting the concrete surface from drying by spraying water or covering with plastic sheets or wet geotextiles. Internal curing can be achieved by using saturated porous aggregates or chemical admixtures that reduce the surface tension of the mixing water, thereby minimizing shrinkage deformations [1,17].

-----------------------------------------------------------------

[1] A.M. Neville, Properties of Concrete. 4th Edition, Addison Wesley Longman Ltd, Harlow Essex, England, 1995.

[2] E.-I. Tazawa, S. Miyazawa, Influence of cement and admixture on autogenous shrinkage of cement paste, Cement and Concrete Research 25(2) (1995) 281–7. https://doi.org/10.1016/0008-8846(95)00010-0.

[3] W. Kurdowski, Cement and Concrete Chemistry, 1st Edition, Springer Science+Business Media B.V, 2014. https://doi.org/10.1007/978-94-007-7945-7.

[4] A. Radocea, Study on the Mechanism of Plastic Shrinkage of Cement-Based Materials, Doctoral thesis, Chalmers, Department of Building Materials, Sweden, 1992.

[5] I. Soroka, Portland Cement Paste and Concrete, 1st Edition, Red Globe Press London, England, 1979. https://doi.org/10.1007/978-1-349-03994-4.

[6] P. Termkhajornkit P. et al. Effect of fly ash on autogenous shrinkage, Cement and Concrete Research 35(3) (2005) 473-482. https://doi.org/10.1016/j.cemconres.2004.07.010.

[7] G.A. Rao, Long-term drying shrinkage of mortar — influence of silica fume and size of fine aggregate, Cement and Concrete Research 31(2) (2001) 171-175. https://doi.org/10.1016/S0008-8846(00)00347-1.

[8] P.-C. Aïtcin, High Performance Concrete, 1st Edition, CRC Press, London, 1998. https://doi.org/10.4324/9780203475034.

[9] D. Ballekere Kumarappa, S. Peethamparan, M. Ngami, Autogenous shrinkage of alkali activated slag mortars: Basic mechanisms and mitigation methods, Cement and Concrete Research, 109 (2018) 1–9. https://doi.org/10.1016/j.cemconres.2018.04.004.

[10] S.L. Mak, D. Ritchie, A. Taylor, R. Diggins, Temperature effects on early age autogenous shrinkage in high performance concretes, Proc. Int. Workshop Autoshrink’98, ed. E.-I. Tazawa, Hiroshima, Japan, E & FN SPON, London, 1998, pp. 155-166.

[11] E. Holt, Early age autogenous shrinkage of concrete, Doctoral thesis, VTT Technical Research Centre of Finland, 2001.

[12] K. Sakata, T. Shimomura, Recent Progress in Research on and Code Evaluation of Concrete Creep and Shrinkage in Japan, Journal of Advanced Concrete Technology 2(2) (2004) 133-140. https://doi.org/10.3151/jact.2.133.

[13] J.W. Bullard, H.M. Jennings, R.A. Livingston, A. Nonat, G.W. Scherer, J.S. Schweitzer, K.L. Scrivener, J.J. Thomas, Mechanisms of cement hydration, Cem. Concr. Res. 41 (12) (2011) 1208–1223.

[14] P.K. Mehta, P.J.M. Monteiro, Concrete: Microstructure, Properties, and Materials, 3rd Edition, McGraw-Hill, New York, 2006.

[15] W. Hansen, et al., Early-Age Cracking: Causes, Measurement, and Mitigation Reported by ACI Committee 231, ACI 231R-10, 2010.

[16] A. Zieliński, A.K. Schindler, 2024. Plastic-Sleeve Test Method to Measure Autogenous and Drying Shrinkage in Paste, Mortar, and Concrete: Test Results, Measurement 237, 115138, https://doi.org/10.1016/j.measurement.2024.115138.

[17] A. Zieliński, A.K. Schindler, 2024. Shrinkage Cracking Potential of Cement Composites Assessed by The Restrained Ring Test, 31st International Conference on Structural Failures, May 20-24, 2024, Międzyzdroje, Poland.